Gajanand Aluminium

Our Quality Assurance

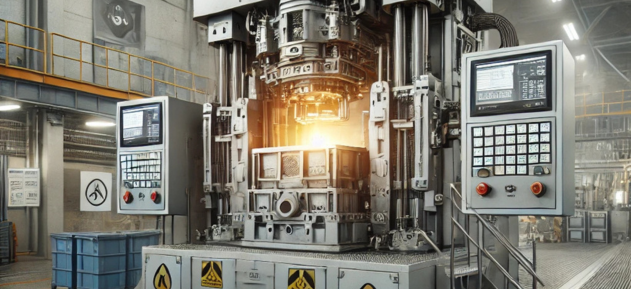

When it comes to quality details for aluminum casting, several key factors play a crucial role in ensuring the final product meets industry standards and customer requirements. Here are the main aspects that define the quality of aluminum castings: